Harnessing the power of safety and operational data can substantially improve safety compliance and performance.

Accessing safety system data and transforming it into meaningful information results in increased machinery productivity and minimises downtime.

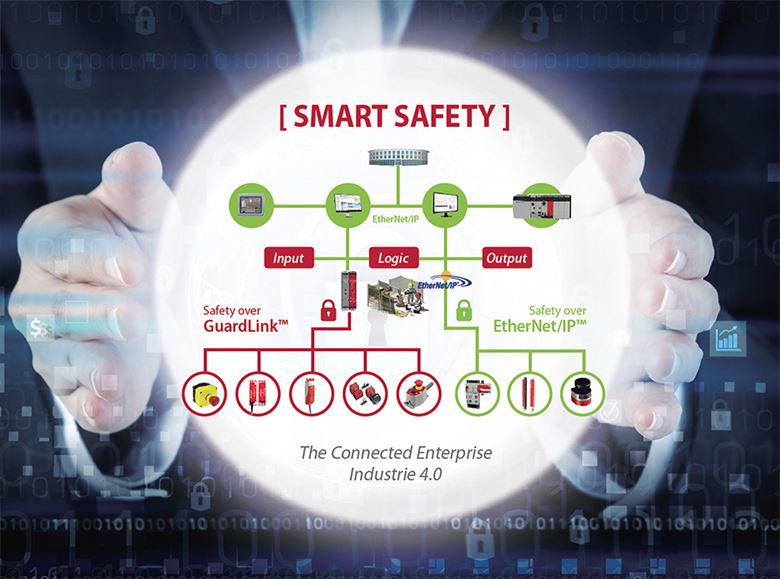

To gain more diagnostic data, traditional safety devices required more complex wiring solutions. With a SMART Safety solution, you can now access more diagnostic data and simplify your wiring system. An integrated SMART Safety solution provides all the data needed to create a comprehensive picture of the status of the machine or production line.

-

Benefits of SMART Safety

-

Challenges to Safety

Increase productivity

By capturing system diagnostics

Minimise downtime

With diagnostic information from the safety system

Enhance protection

Protect your people and assets

Broad product portfolio

Benefit from the broadest portfolio of safety products, solutions and services

Worker behaviours

The number 1 reason for safety system failures is that the solution is bypassed.

Evolving workforce

A major workforce shift is underway worldwide, and the safety implications are significant.

Machinery stoppages

Companies often have minimal visibility into why or when machinery stoppages occur.

Regulatory compliance

Compliance with complex global safety standards is increasingly essential but also challenging.

Emerging technologies

Advanced safety technologies enable companies to address safety & productivity in new ways,

Data management

Outdated data collection and reporting methods. Manual entry of safety data for logs, reports, etc.

Pillars of Safety

SMART Safety in action

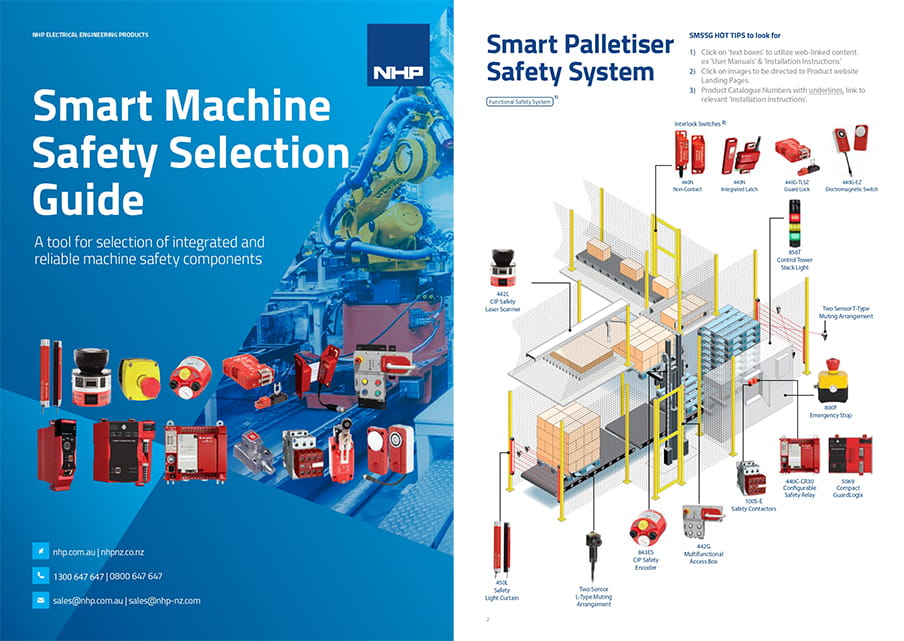

Learn more about practical applications that can address your challenges and take your site to the next level.

-

Inputs

GuardLink Device Level Safety Network

GuardLink is a low level network providing device level diagnostics for safety components. It helps simplify safety networks when using safety devices that do not have EtherNet/IP connection. It offers increased diagnostic information to traditional hard wired systems and is a modular Plug-and-Play network requiring no configuration.

SafeZone 3 Laser Scanner

The SafeZone 3 Safety Laser Scanner is a compact device that supports up to 2 zones with simultaneous monitoring (warning and safety fields for each zone). It uses Safety over Ethernet/IP technology and offers two ethernet connections for Device level Ring topology. The configuration software simplifies the programming and Add-On-Profiles are available in Studio 5000 Engineering Environment.

450L GuardShield POC Safety Light Curtains

The 450L GuardShield POC safety light curtains are unlike traditional safety light curtains, which are based on separate transmitter and receiver units. This next generation light curtain system features patented technology, which allows each transceiver to be used as a transmitter or receiver via an innovative plug-in module. This advanced technology greatly reduces stock and provides a flexible, cost-effective safety solution.

Lifeline 5 Cable Pull Switches

The 440E Lifeline 5 Cable Pull Switches are microprocessor-based solutions that bring advanced features and diagnostics that help enhance safety and improve productivity. These switches offer features and functions that simplify setup and allow for more efficient maintenance and troubleshooting.

450L GuardShield POC Safety Light Curtains

The 450L GuardShield POC safety light curtains are unlike traditional safety light curtains, which are based on separate transmitter and receiver units. This next generation light curtain system features patented technology, which allows each transceiver to be used as a transmitter or receiver via an innovative plug-in module. This advanced technology greatly reduces stock and provides a flexible, cost-effective safety solution.

843ES CIP Safety Encoder

Encoders are designed for safety applications that require speed, direction, or position monitoring safety functions. By providing auxiliary feedback directly through an EtherNet/IP network on CIP Safety, it makes it easier to achieve the desired safety integrity or performance level by reducing the number of components needed and utilizing the already available advanced drive safety instructions

-

Logic

GuardLogix 5580 Safety Controller

The GuardLogix 5580 safety controller integrates high-performance standards and safety control in the same controller and is programmed using Studio 5000 design environment. It offers scalability in performance and use as the primary controller (used without a partner) and is certified for use up to SIL2/PLd. With a safety partner, the controller is certified for SIL3/PLe use.

Compact GuardLogix 5380 Safety Controller

The Compact GuardLogix 5380 safety controller integrates high-performance standard and safety control in the same controller and is programmed using Studio 5000 design environment. Versions are available for use in either SIL2/PLd or SIL3/PLe applications. SIL2 versions offer Motion and Non-Motion variance which helps customer further optimize their machine design.

Flex 5000 I/O

The FLEX 5000 I/O is a reliable and flexible distributed I/O solution, which allows you to choose your I/O to meet your operational needs. FLEX 5000 I/O enhances communication with 1 Gb EtherNet/IP connectivity, which offers higher speed and increased bandwidth. To provide flexibility in your network architecture, FLEX 5000 I/O includes 2 copper or 2 fibre ports (SFP) and support for DLR, Star, Linear, and PRP topologies. Designed for use in a broad range of applications, the FLEX 5000 I/O operates in -40...70 oC (-40...158oF) temperatures.

Compact 5000 Safety I/O

The Compact 5000™ I/O modules provide high-performance control in a compact design, and expand the performance capabilities of the Logix platform. They are the local I/O modules in a CompactLogix™ 5380, Compact GuardLogix® 5380, or CompactLogix 5480 system and safety options are available. These modules are the ideal distributed I/O solution on an EtherNet/IP network for CompactLogix 5380, Compact GuardLogix® 5380, CompactLogix 5480, ControlLogix® 5580, and GuardLogix 5580 controllers with safety module restrictions. They are great for applications with high-processing requirements.

ControlLogix I/O

The Bulletin 1756 ControlLogix® chassis-based modules provide a full range of digital, diagnostic digital, analog, motion control, specialty I/O, and compute modules to meet your application needs. You can use any of the chassis-based modules in the local chassis of a ControlLogix controller or in a chassis linked to a ControlLogix controller across ControlNet™ or EtherNet/IP™ networks. The range now includes Safety I/O.

CR30 - Software Configurable Safety Relay

Simplified safety PLC, ideal for applications requiring many dual-channel safety circuits. It can be configured via software selecting certified safety function blocks.

-

Outputs

Drives & Motors

Safety options can help reduce machine downtime and increase productivity. To help you protect both your personnel and equipment, a variety of PowerFlex® drives are available with safety features. The PowerFlex 525 AC drives include embedded Safe Torque-Off as a standard feature. Safe Torque-Off is an optional feature for the PowerFlex 40P, 70, 700H, 700S, and 750-Series AC drives, which also support Safe Speed Monitor functionality. Additionally, you can configure drives without a safety option using the MSR57P Safety Relay.

ControlLogix Safety I/O

A wide selection of PowerFlex AC and DC variable frequency drives and Kinetix servo drives that are all designed for flexibility, productivity, safety and ease of use. Our VFDs handle both low voltage and medium voltage applications, with a wide range of power ratings. Kinetix servo drives offer the right size and feature set to handle a broad range of applications from single axis component drives to multi-axis modular drives. We offer solutions that are designed to help you simplify machine design while you improve system performance. Various motors that are designed for optimum performance and service life round out this offering.

Safety Contactors and Relays

100S Safety Contactors provide safe isolation of hazardous motion loads, using mirror contact performance. Mirror contacts provide reliable indication about the open or closed status of the main power poles.

-

Software

Design

Design software helps you maximize automation productivity through reduced design time, creating new ways to lower costs by creating consistent, modularized solutions that improve manufacturing efficiency.

HMI

FactoryTalk View provides robust and reliable functionality in an HMI solution that scales from a stand-alone, machine-level HMI to a distributed visualization solution. With FactoryTalk View, HMI challenges in process, batch and discrete applications are managed in a single software package that extends beyond the walls of your facility to deliver critical visibility on demand, improving the productivity of users at every level of your organization.

Manufacturing Intelligence

Enterprise manufacturing intelligence software helps to free the data currently locked within your control and business systems and deliver actionable information to improve productivity, increase yield and reduce costs. Rockwell Automation Manufacturing Intelligence solutions produce analytics that help in decision making, when and where you need it, to improve plant efficiencies and Overall Equipment Effectiveness to save time and money.

Configuration Collaboration

The Bulletin 1756 ControlLogix™ chassis-based modules provide a full range of digital, diagnostic digital, analog, motion control, specialty I/O, and compute modules to meet your application needs. You can use any of the chassis-based modules in the local chassis of a ControlLogix controller or in a chassis linked to a ControlLogix controller across ControlNet or EtherNet/IP networks. The range now includes Safety I/O.

Tools

Complex machinery, safety standards, and contemporary equipment require a deep understanding of each to implement safety solutions that protect workers, improve productivity, and achieve compliance.

Below, we've provided you with a variety of tools to help you achieve these goals.

Safety automation builder

Invaluable software designed to help simplify machine safety system design and validation.

Pre-engineered safety functions for machines

Machine safety can be developed by combining blocks of safety functions to provide a complete safety solution.

Safety ROI tool

The evidence is clear: safety is good business. Find out how to quantify the savings and productivity gains from safety investments.

Safety Maturity Index

The Safety Maturity Index is an invaluable tool that offers visibility into safety processes.

Machinery Safebook 5 - A Guide to Machine Safety

Practical guide to the principles of machine safety, legislation, theory and practice.

People and services

Together with Rockwell Automation, the world's largest industrial safety provider, we help to reduce injuries and costs while improving productivity at every phase of the Safety Life Cycle.

Safety services are delivered by experienced staff who are safety qualified, many with TUV Rheinland Machinery Safety certifications. We have people who are TUV Functional Safety Experts, Engineers and Technicians to help customers with their holistic safety lifecycle.

The Safety Life Cycle is a clearly-defined process that helps to maximize productivity and improve safety by identifying the steps required to assess and mitigate machinery risks. The Safety Life Cycle can be seen and downloaded in this document.

Safety assessments

Services that help to evaluate plant risk and support well-informed decisions that improve employee and machine safety.

Design services

Comprehensive circuit design, proper application of devices and design review to improve overall safety.

Resources & Downloads

eBook

Harnessing the power of safety and operational data can substantially improve safety compliance and performance.

Allen Bradley - Smart safety

Get more from your safety investment

Selection Guide

A solution incorporating Smart Safety devices enables safety professionals to transform the way they monitor and manage safety.

Safety Automation Builder and SISTEMA

Rockwell Automation Launches New Tools to Simplify Machinery Safety-System Design