Verification requirements

How to verify a switchboard design

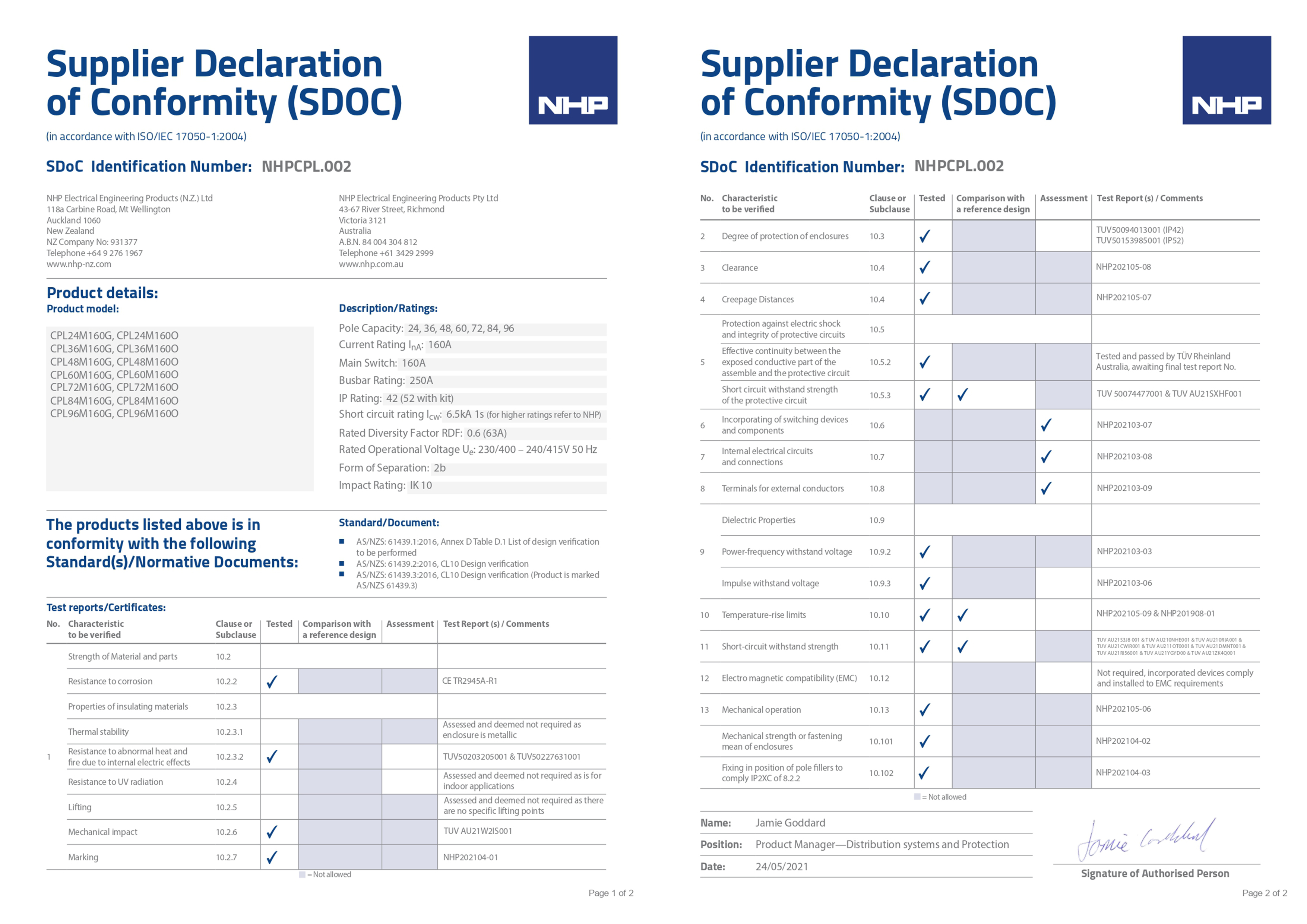

To comply with AS/NZS 61439, all switchboards and distribution panelboards require documentation to prove their performance characteristics meet or exceed the requirements for the manufacture as specified. This documentation comes in two parts:

- Design verification - compiled by the assembly manufacturer, proving their design is the same or better than the

verification documentation from original manufacturer. If the assembly manufacturer makes their own design, they are the original manufacturer.

If the assembly manufacturer makes any modifications to the original manufacturer’s design, then the assembly manufacturer is responsible for providing design verification for that modification. - Routine verification - checks completed by the assembly manufacturer on the assembled switchboard.

Design verification

AS/NZS 61439-1 Table D.1 gives a table of characteristics to be verified and nominates which of the 3 methods below are available to use for each characteristic.

VERIFICATION BY TEST

- The switchboard or relevant section of the switchboard is designed and assembled the same as the tested assembly.

VERIFICATION BY COMPARISON

- Verification by comparison to a reference design requires demonstrating that the new characteristics are the same or better (less onerous) than the tested design.

VERIFICATION BY ASSESSMENT

- This includes the correct application of design rules and calculations, including use of appropriate safety margins.